Air Balancing

The process of optimizing an HVAC system to ensure that air conditioning outputs are consistent, and temperatures are comfortable in all rooms of the house or building. Air balancing hoods are used to measure the amount of air at each grille.

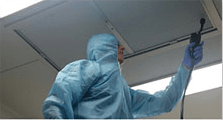

HEPA Filter Test

HEPA filter integrity testing is typically performed on supply air or exhaust air HEPA filters using a photometer to scan the filter surface for pinhole leaks that could allow the transmission of contaminant particles that would be unacceptable in a critical application.

Racks Inspection

Racks inspection is a visual inspection of warehouse and storage systems (typically pallet racking or mezzanine floors), taken to ensure that the racking is safe to use.

Thermography

The non-destructive test method that may be used to detect poor connections, unbalanced loads, deteriorated insulation, or other potential problems in energized electrical components.

Load Testing

It is used to identify whether a structure, component, part or product is suitable for its intended use. Testing consists of monitoring how a test sample reacts when a static or dynamic force is applied to it.

Instrument Calibration

It is one of the primary processes used to maintain instrument accuracy. Calibration is the process of configuring an instrument to provide a result for a sample within an acceptable range. Eliminating or minimizing factors that cause inaccurate measurements is a fundamental aspect of instrumentation design.

Pressure Testing

The non-destructive way to guarantee the integrity of equipment such as pressure vessels, pipelines, plumbing lines, gas cylinders, boilers and fuel tanks. It is required by the piping codes to confirm that a piping system is able to bear its rated pressure and it has no leak.

Thermal Mapping

The process of installing data loggers to determine if a storage area can maintain temperature / humidity within defined limits (Fridges, Freezers, Rooms, Warehouses and Incubators etc.). Sensors are distributed throughout the unit/room in pre-defined locations to confirm it performs within pre-defined set points.

Thickness Monitoring

An ultrasonic thickness gauge is a measuring instrument for nondestructive investigation of a material's thickness using ultrasonic waves. It is used for ultrasonic thickness measurement (UTM) of the thickness of a solid element. Ultrasonic thickness gauges are designed to improve safety and ensure reliability of materials subject to corrosion or erosion. It is also used for monitoring pipelines.

Earth Resistance Test

Poor grounding not only increases the risk of equipment failure; it is dangerous too. Facilities need to have adequately grounded electrical systems so in the event of a lightning strike, or utility overvoltage, current will find a safe path to earth. That is why it is highly recommended to test earth electrodes with an earth resistance meter.

Dye Penetrant Test (DPT)

Also called as Liquid Penetrant Inspection is an efficient, economical and widely used non destructive test method to detect surface-breaking discontinuities in all non-porous materials.

COMPRESSED AIR TESTING

Compressed air testing involves analyzing the air for the presence of various contaminants, such as water vapor, oil, and other particulate matter that could impact the quality of the compressed air and potentially cause damage to equipment or harm to workers.